This article is part of a blog series on wearables, exploring what they are and if your business is agile enough to enable collaboration.

The continuous development of technology helped us to evolve our buildings, infrastructure, and commercial facilities. The new tools allow us to construct bigger and more sturdy structures.

The construction industry has been slow in adopting new technologies but has been able to discover amazing innovations in safety. New ideas are developed daily for our workers. The combination of Artificial intelligence and the Internet of Things gave birth to wearable technology, which is penetrating the market at a fast speed and benefitting the whole industry.

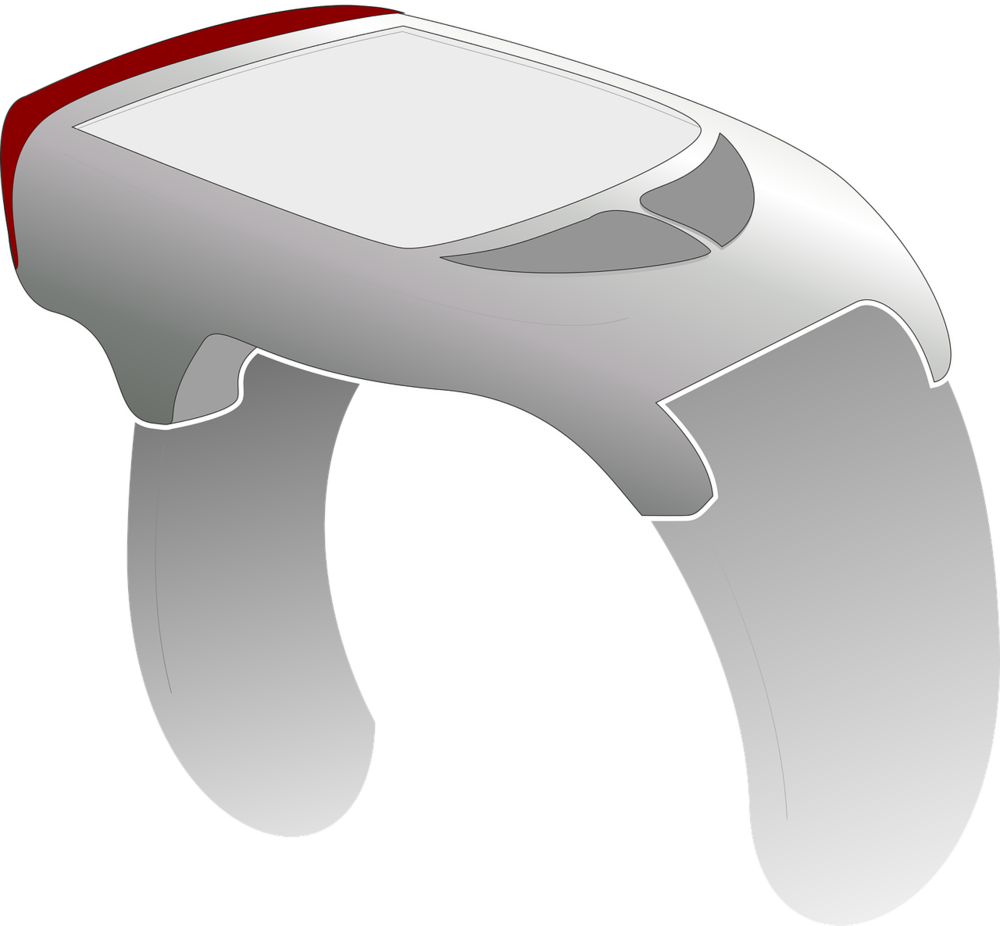

We have not been able to find a commonly accepted definition of wearable technology, but the key components of wearables are as follows:

The most frequent sensors used in wearables are:

The data collected is used to measure:

The wearers can interface with the devices via:

Some tracking devices only assemble data that are interpreted and analyzed by other devices.

Let’s contemplate the benefits of wearable technology for the construction industry.

It is well-accepted that the construction industry is prone to accidents. Eliminating falls would save more than 300 lives every year in the USA. The statistics show that:

Safety on construction sites is of paramount importance. Issues are of high interest. Wearable technologies can help to increase safety on site by:

Safety improvements are considered to be the main benefit of wearable technology.

For example, smartwatches can monitor each individual person on a construction site to inform the safety manager in real time if employees:

Wearable technology increases workers’ efficiency helping them to perform their tasks. For example, exoskeletons will:

If you integrate wearables with other technologies you can streamline your processes to improve your onsite data collection. Better collection of data boosts your efficiency by:

For example, you can use wearables to feed your smartphone applications that will automatically, in real time, generate reports.

When building an asset collaboration and communication is critical.

Wearable devices can help you to communicate by:

For example, a smart hard hat can bring new information to a supervisor, instantaneously, so they can update their data in real-time and produce accurate reports on the advancement of the work on the construction site.

Wearable devices should, if required, allow workers to share:

For example, a supervisor spotting some employees, approaching dangerous areas, with a risk of them being injured, can send vibrations directly to the worker’s safety vests warning them of the potential hazard. In a noisy environment where alarms are hard to be heard this feature is very convenient.

The construction industry has a very poor image in young workers' eyes. With baby boomers coming to retirement age, you need to attract younger workers. The use of technology can change the perception of the construction industry of the young generation whilst current employees are retiring.

Millennials and younger generations expect to find in the workplace what they are used to in their private lives:

To satisfy the younger workers' expectations and attract them to the construction industry we should provide them with wearables. This will be a gigantic step to prove to them that the industry is up to date with the latest developments.

Wearables not only can attract young people to your company but also make your existing workforce happy and increase their job satisfaction and retention as they:

Managing and planning the use of resources, employees, machinery, and material may give a competitive edge to a construction company bidding for a new job.

With the help of wearables, you can keep an eye on your staff to see:

Despite the introduction of new technologies in the construction industry recently, a few problems have not been resolved.

In project management, the construction industry still faces quite a lot of challenges from the strategy stage to the in-use stage.

Wearable device usage helps monitor, analyze and manage:

To achieve your goals at every stage of a project, wearables will be very handy to help you to:

Unfortunately keeping up with the rapidly changing technologies in an industry as competitive as construction is quite daunting.

Managing and understanding the risks and liabilities associated with technological developments is also a hurdle.

In this article, we highlight the risks and challenges associated with the usage of wearables in the construction industry. The key elements a company should put in place to overcome these challenges are to be able to:

You can use wearables to reduce time-consuming issues in the construction industry like:

Wearables can detect and warn of safety hazards but you have to make sure that your data are reliable and of high-quality to avoid any regulatory compliance pitfalls.

In legal disputes, wearables can be useful if used appropriately:

Potential pitfalls can also exist as there are plenty of legal issues associated with wearables:

As wearables are supposed to prevent safety incidents, if they fail to perform properly and an employee is hurt, who is liable for the failure:

The answer is not easy, traditional negligence and product liability law will guide the outcome of this issue.

Companies may want to mitigate this risk by:

Legal issues related to data collected from wearables may bear consequences if they fail to secure the data to:

To minimize the risks you should:

Tracking whether or not employees are working would be useful information if a wage and hour dispute arises. The data collected by wearables are reliable and objective data to resolve potential claims.

In countries with more employee-friendly employment laws, such as France, mandatory wearable policies may pose a problem.

Some issues that you should address when implementing wearables are:

Monitoring work hazards should be done by everyone on the team. Improving workers' awareness reduces or avoids accidents, reducing the overall risk of a project. You should ask yourself the following questions when you implement wearable technology:

Despite all the benefits wearable technologies bring to the construction industry they also come with challenges:

It is of paramount importance that you stay informed of the current evolution and emerging technologies in the construction industry to ensure you are on the leading edge of innovations of safety and efficiency.

At Driving Vision, we believe that the future of wearable in the construction industry is great and will completely revolutionize the traditional way of operating. We can help you to decide if you need to invest in technology.

Our technology diagnostic looks at the best way to incorporate new technology into your workflows. It looks at how to move your organization to cloud computing so you can open up new possibilities for your daily planning tasks. The technology appraisal report will help you to explore what investment is required to improve your projects’ productivity and collaboration as well as the ROI you can expect.

A Driving Vision expert will conduct the interviews online and will issue a report and discuss our findings with you. Together we will decide the best way to implement the solutions at your pace and according to your budget.

Implementing BIM can be daunting, but Driving Vision is here to help you at the pace you are comfortable with. Get started by getting in touch now

Seamless Data Transfer

Enhances collaboration between team members

Allows you to build green constructible assets on budget and on time