This article is part of a blog series, in which you can find out how 3D printing is used on construction sites, such as replacing broken parts, construction equipment, and even building new houses. We have all heard the buzz around 3D printing in the last ten years but is it merited?

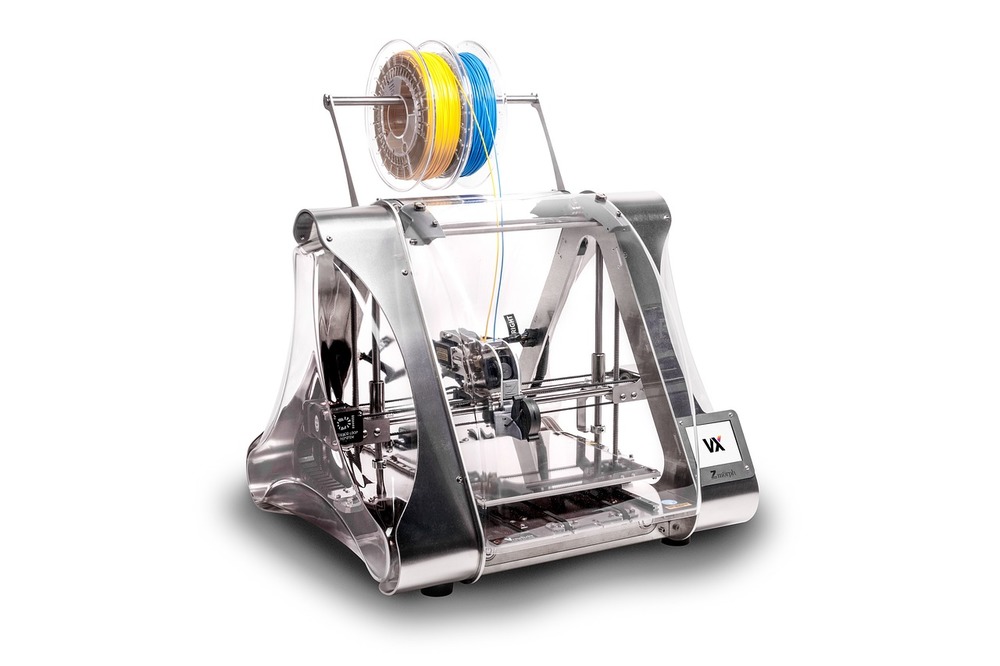

Although 3D printing technology was developed for product prototyping purposes, it is now a key player in a variety of industries such as medical, aerospace, and toolmaking, and is now emerging in the construction sector.

With 3D printers now able to print walls and process cement, the technology could transform construction as we know it. But is it a key long-term solution?

When did 3D printing start?

3D printing started in the mid-1980s with stereolithography, or SLA, a high-powered laser that turns a liquid resin into a solid material. SLA builds a product layer-by-layer, which makes it an additive technology. It is still the most popular 3D printing technology, even today.

Since then, many more types of 3D printing have come on the market, including:

- selective laser sintering (SLS)

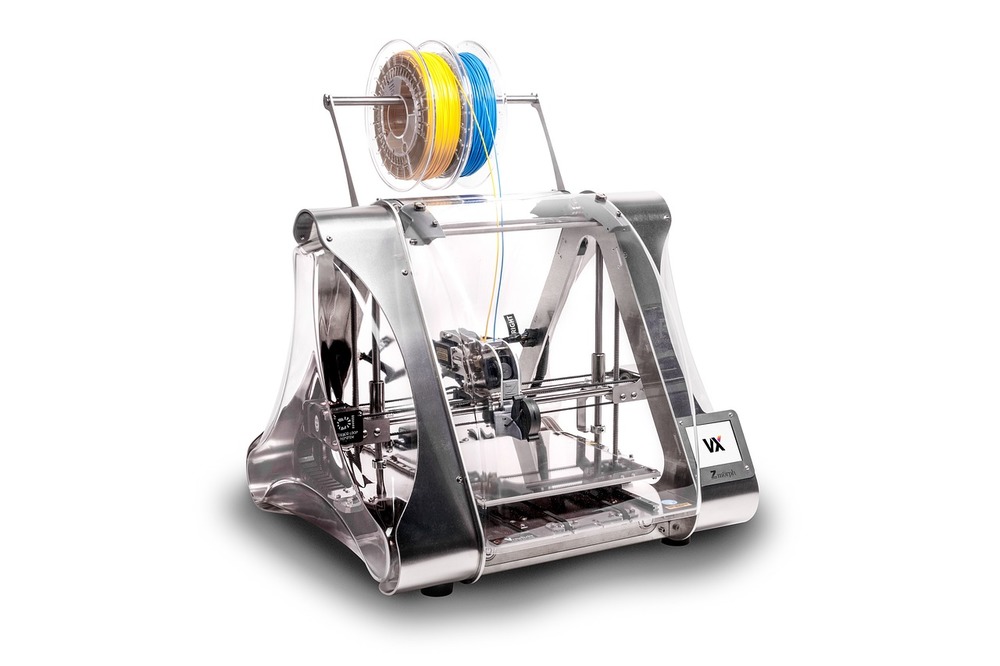

- fused deposition modeling (FDM)

- direct metal deposition (DMD).

3D printing has evolved to be used in building information modeling (BIM) by architectural firms to build scale models. It has now been used in more resourceful construction projects. Some examples include:

A canal house - constructed by various parties researching the possibilities of 3D printing in architecture, using a fused deposition modeling printer developed by DUS architects called the Kamermaker (Room builder). They collaboratively connected design, science, culture, building, software, communities, and the city. The project was initiated by DUS architects in Amsterdam North, it opened to the public on March 1, 2014.

A 3D-printed mansion - designed and built, on-site in 45 days in 2016, by HuaShang Tengda a Chinese architecture firm, while other 3D-printed structures were manufactured at separate facilities and assembled on-site later. The company created an entirely new print-process technology that utilizes concrete, specifically for the job. Before starting the machine, a construction team installed the building’s frame, including rebar support and the home’s plumbing.

Many construction companies are entering into partnerships with 3D printer providers for constructing homes using 3D printing technology. For instance, in March 2021, 3Strands partnered with ICON, a construction technology company. Through this partnership, the former company planned to leverage the 3D printing technology of ICON to develop two- to four-bedroom homes in Texas.

The growth of the 3D printing market in construction

According to the 3D printing construction market size, share & trends analysis report

, the global 3D printing construction market size was valued at USD 18,2 Million in 2022 and is projected to grow at a rate (CAGR) of 101.9% from 2023 to 2030.

3D printing technology is able to:

- create customized and unique structures

- make models for bespoke building projects

- produce layers of concrete, plastic, and metal, layer after layer to build a structure.

3D printing and green construction methods are used more and more by construction companies to reduce costs and build energy-efficient buildings. The additive manufacturing (AM) process is used to build:

- a highly precise and customizable structure

- quicker than traditional structures with less waste

- complex building structures using modeling software programs

- enhanced efficiency with a reduced labor force.

The drivers for the market growth are:

- prototyping

- designing

- creating accurate end products

- reducing manufacturing expenditure.

The market is projected to grow due to the increasing adoption of building information modeling (BIM).

A report from Essentium Inc about the 2021 trends in 3D printing at scale shows how 3D printing is helping to construct sustainable buildings:

- 100% of the respondents said it is important

- 75 percent said it is “very” important.

3D printing construction companies move toward the green buildings concept, to:

- eliminate waste

- consume less energy and raw materials.

Below are some of the findings of the survey:

Reduced waste

Forty-five percent of respondents said 3D printing sustainability initiatives have the biggest impact on waste reduction as they use only the material that is required.

Lowered overruns

With 3D printing, you can:

- design, print, test, iterate, and finalize in a very short time

- produce complex geometries in a single piece, reducing time and cost.

Little logistic is needed

With 3D printing, you can reduce warehousing and capital expenses costs as you can produce parts when needed.

Decreased carbon footprint.

Thirty-seven percent of respondents believe that 3D printing impacts their carbon footprint. AM allows on-site printing and minimized warehousing, so you can implement low carbon footprint solutions.

Less transportation costs

Using a 3D printer, local suppliers can design, produce, package, and distribute products, thus reducing their transportation costs.

Short supply chains

When manufacturers use 3D printing, they can:

- decrease lead time

- reduce production costs

- diminish the carbon footprint

- increase agility.

The growing construction sector in emerging countries is expected to drive market growth over the forecast period, by:

- putting a high emphasis on eco-friendly practices

- adding new requirements for affordable housing solutions.

Governments of different countries and regional authorities & organizations are encouraging innovation such as 3D printing. Some are also encouraging innovation through developments across public infrastructure and legislation, which will increase adoption.

Adverse market factors

Capital investment associated with 3D printing construction is expected to hinder market growth because:

- the materials used in commercial and industrial 3D printers are more expensive than those used in traditional construction processes

- there are material constraints

- machinery has limitations

- of intellectual property concerns

- of few skilled workers

- the COVID-19 pandemic adversely affected the growth of the global market.

Construction method innovation

The global market has been further segmented into extrusion, powder bonding, and other (additive welding).

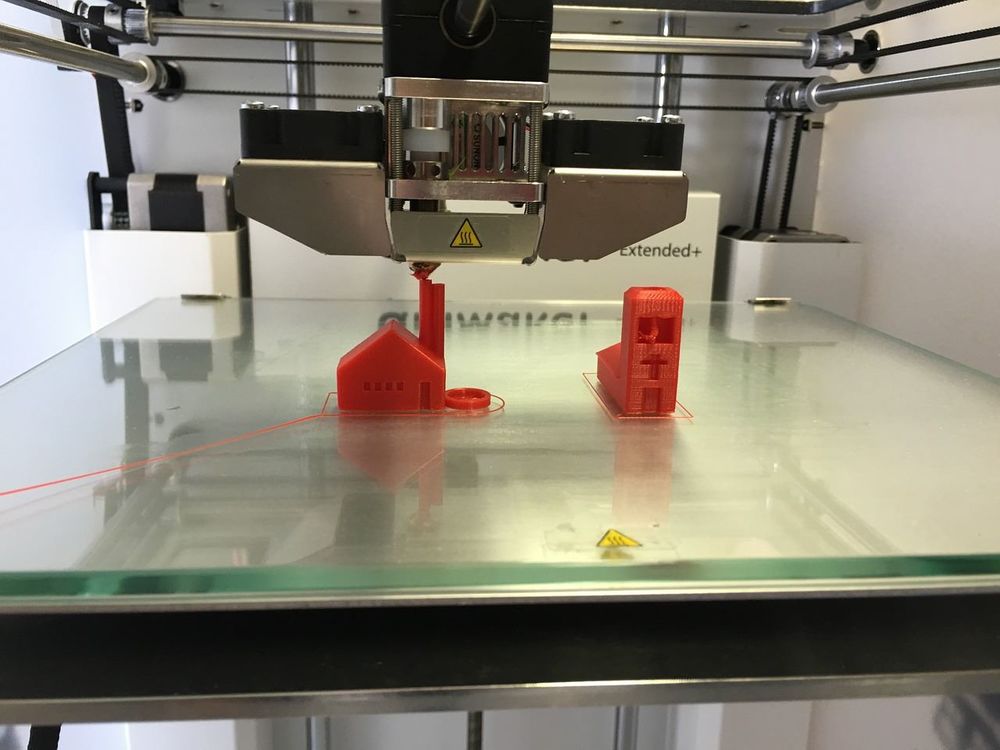

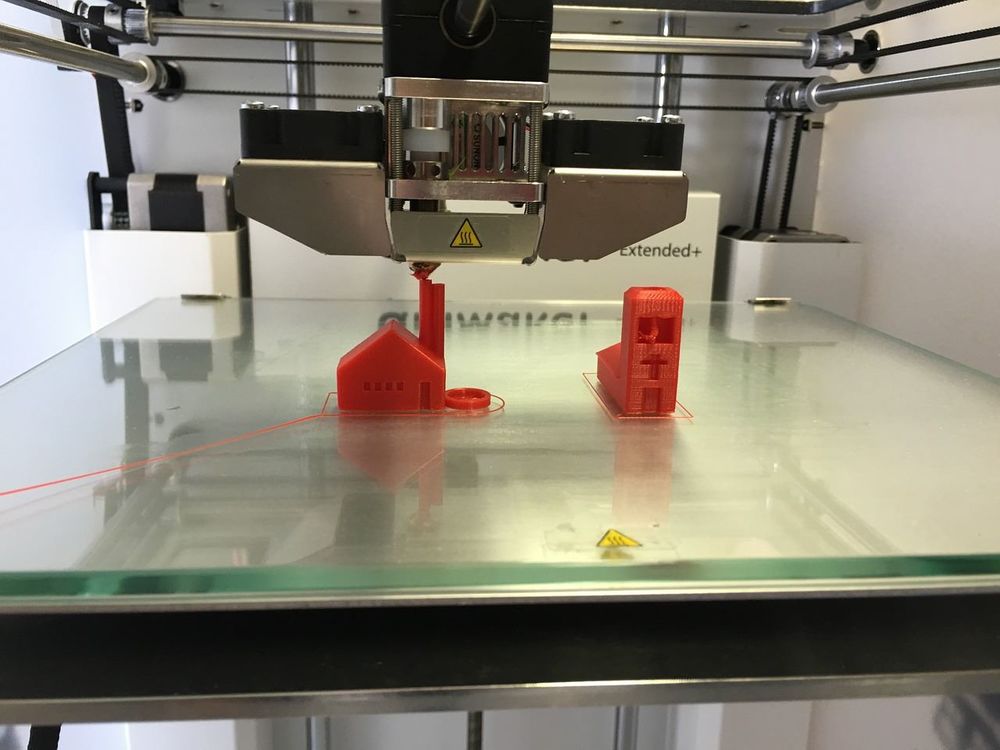

Extrusion 3D printing is also known as fused deposition modeling (FDM), which is one of the additive manufacturing techniques used for prototyping, modeling, and production applications.

The powder bonding segment is anticipated to register significant growth over the forecast period. The demand for this method is high as it is faster, simpler, and more accurate to produce a complex framework. This method is:

- less labor-intensive

- less time-consuming.

3D printing in the construction industry is used for constructing complex building structures using modeling software programs.

Types of 3D printing in construction

There are three main types of 3D printing in construction:

Robotic arm extruders

Also named contour crafting, the method uses an arm or a crane that moves back and forth:

- releasing materials and creating layers

- installing rails around construction spaces

- changing position and height when required

The method is used for small 3D printing activities. For example, when mixing concrete, while you are building, you could prevent it from hardening too quickly by using a robotic extruder arm.

Sand layers

These 3D printers are used to discharge layers of sand in order to build structures. How does it work:

- the layers are thickened up to the right level

- the printer sprays a small amount of water over the sand, hardening it.

You can use this method for smaller structures or materials in construction. For example, lightweight construction and demanding or complex geometries built using sand printers have the possibility to optimize the manufacturing process and reduce costs.

You can combine 3D printing technology with other technologies, for example welding to solidify the materials and then printing the product to create structures such as bridges that have no foundation.

In conclusion

The implementation of 3D printing technology offers:

- high accuracy

- improved efficiency

- reduced labor cost

- greater speed.

The growing adoption of 3D printers in the construction sector is driving market growth for:

- prototyping

- designing

- creating accurate end products

- reducing manufacturing expenditure.

A rise in the adoption of green projects globally is also one of the major factors accentuating the market growth.

3D concrete printing is more and more used as an alternative to conventional concrete construction to reduce cost, labor, and time, and increase productivity.

Metal 3D printing is mainly used for designing façade nodes and other connections. It also offers opportunities to create:

- internal stiffening

- non-prismatic sections

- openings

- functionally graded elements, through controlled heating and cooling.

The 3D Printing market in construction is here to stay and will grow fast.

Driving Vision's technology appraisal looks at the best way to insert new technology in your workflows and how to move your organization to cloud computing so you can open new possibilities for your daily planning tasks and make sure your data never leaves the optimally secured data center.

A Driving Vision expert will conduct the interviews online and will discuss with you the report and our findings. Together we will decide the best way to implement the solutions at your pace and according to your budget.

Implementing BIM can be daunting, but Driving Vision is here to help you at the pace you are comfortable with. Get started by getting in touch now