We offer you and your projects’ partners a win-win solution based on a solid, long-lasting, fruitful relationship

You outsource the mundane & concentrate on what you do best

This article is part of a blog series ,which explores the future of Artificial Intelligence in construction.

Artificial Intelligence (AI) has already had a big impact on the construction industry. There are various ways it can be implemented:

The ultimate goal for AI in construction is to:

A recent McKinsey study called artificial intelligence “construction technology’s next frontier.” Said that despite a slow rollout, the future for the technology is such that if you ignore its emergence, you put yourself at risk. The report predicts that “this effort will lead to AI playing a more significant role in construction in the coming years.”

As reported by For Construction Pros, a study from Harvard Business Review shows that:

As the fear of the unknown around AI subsides, more construction companies will reap the benefits of this transformative technology.

A better understanding of AI, Machine Learning (ML), and analytics will see the construction industry adopting AI more widely to play a more significant role in the coming years.

We will look at the various phases of a project to determine how AI can improve its efficiency:

The processes of developing an idea for a construction project, designing the building, and planning need to be streamlined and automated to deliver your project on time, on quality, and on budget.

In large construction projects such as infrastructure buildings, there are many examples of projects failing due to inaccurate planning.

Generative design, an AI-based design exploration process, can access a database of previously built projects. The machine will produce various design scenarios based on the knowledge acquired from the plans in the database. All designers and engineers, have to do, is to input into the machine the design goals and parameters needed for the project. The generative design software defines the necessary parameters and gets the best possible solution and several alternatives in an instant. This is a major improvement over the traditional method enabling the design and planning to be timely, of high quality, and less costly.

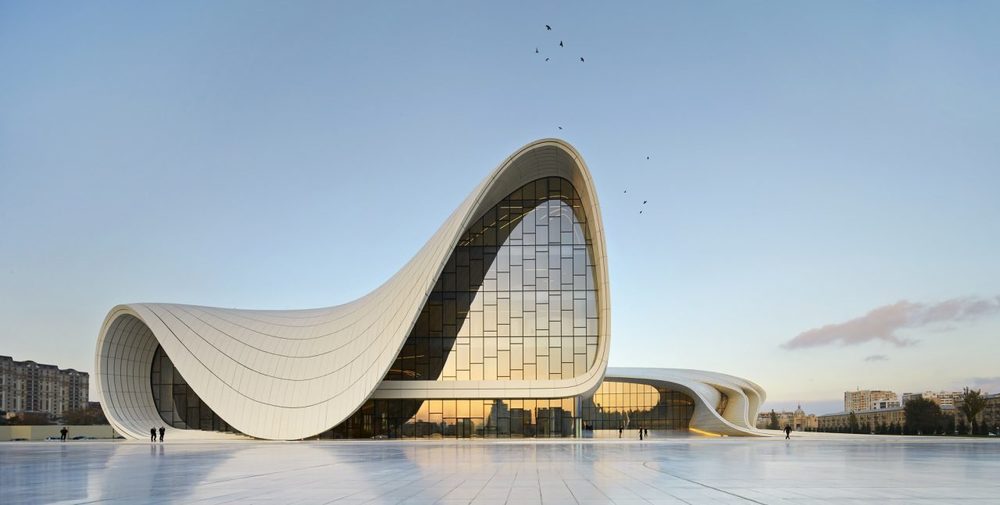

The Heydar Aliyev Centre is a landmark in Baku, the capital of Azerbaijan. The structure looks like a spaceship more than a functional building. The generative design software made possible the design of such a peculiar shape that meets all design parameters. This building is a great piece of public architecture including a conference hall, a library, and a museum. AI drastically simplified the process and helped to carefully plan the perfect interior design using an algorithm. Artificial neural networks detect clashes instantaneously without engineers, find the right solution and change the plans accordingly.

The logistical inefficiencies of construction sites impact productivity:

AI-based solutions, automating the construction process, can increase the productivity of the construction execution, keeping all stakeholders informed by improving:

The construction process can be accelerated by continuously comparing the digital twin of the building, designed with the Building Information Modeling (BIM) in the cloud, versus the physical building.

Using robots and drones, AI can track the progress of the physical building against the plan stored in the BIM cloud, automatically finding errors/deviations from the original building plan during the construction phase. The early reaction will avoid unnecessary expensive reworks.

Early detection of potential delays and changes could potentially trigger the algorithm to perform an automatic change in the construction schedule in BIM, optimize the site logistics and inform all stakeholders electronically.

An AI-driven construction process could therefore be the key enabler for just-in-time delivery of construction supplies.

The importance of increased safety at construction sites is vegery important to cut accidents and injuries. AI computer vision combined with cameras mitigates risks and reduces the number of accidents greatly.

AI-based solutions can be taught to inform staff whenever it detects possible safety hazards (e.g. when a tool is not stored correctly or workers are not wearing safety gear). The site manager is alerted immediately so he can prevent the safety hazard from happening.

Chinese scientists say that by 2024 they will build a 590-foot-tall dam, at Yangqu, using AI and 3D printing without the need for human workers.

If and when it is completed, the ambitious project will be the world's tallest structure built using 3D printing processes.

The system will be used to manage an automated assembly line made of unmanned trucks to transport construction materials to the worksite. When the materials arrive, unmanned bulldozers and pavers build the layers of the dam, and then rollers equipped with sensors press each layer to get them steady and durable.

The only manual intervention will be the mining of the construction material.

The system will also allow monitoring progress continuously without safety concerns for human workers.

The AI system and its army of robots will help eliminate human error, such as:

If successful, the building method could provide a blueprint for other construction projects, such as road construction, Liu's team said.

China, which is facing a plummeting birth rate and possible labor shortages, has in recent years turned to automation to keep its construction industry going.

Artificial Intelligence (AI) integrated into technologies and structures in “smartly built assets” will help improve the facility management processes, providing intelligent automation for climate control, security, cleaning, maintenance, lighting, and more.

Machines doing tedious, repetitive tasks or complex calculations currently made by humans will make life easier for your existing labor force. It will also help:

How will it work? AI empowers machines and networks to:

We are reviewing below four major applications that make the Facility Management (FM) process easier.

A whopping $647 billion is lost globally each year, per the International Society of Automation.

The main causes of down time are: - weather changing over the four seasons - machines are used more frequently - appliances and machinery are getting old, and faults happen.

AI FM software inspects and deciphers historical data, on construction bad performances, repairs, and labor requirements. The software can then automatically generate order forms and send them to the appropriate vendors.

Historical data are produced by IoT device’s monitors and send alerts when functionality abnormalities are detected. The software recognizes the issues, projects the time and cost to fix them, and schedules qualified labor.

AI FM software simplifies and automates the invoicing process by organizing the work orders, using statistical methods, to electronically open, close, approve, and pay the required labor and material by reusing data from past orders of similar scope.

With AI automated maintenance and breakdown detection, small facilities management teams can manage a lot of buildings and assets. The FM employees are able to focus on important tasks as the software reduces significantly the machine downtime and reduces costs.

The largest cost category for businesses, after wages, are the energy consumption on heating, cooling, ventilation, electricity, and water. On average, Energy represents about 19% of total expenditures for an office building, which is a significant operational cost that deserves attention to cut costs and improve environmental awareness.

AI FM software uses predictive analytics to monitor and to optimize in real-time the various sources of your electricity consumption.

Building Automation Systems (BAS), check temperature issues quarterly to:

Beyond real-time monitoring, AI software combined with IoT and remote management dashboards can:

Security is well known as a major concern for most FM teams, but very few teams are prioritizing it until an infringement happens. Ai surveillance systems can alleviate this issue by automating the review process.

Access control, CCTV surveillance, intrusion detection, package screening, and weapon detection are just a few examples of commonplace data-driven security technology in FM. While useful on their own, these applications can be enhanced and made even smarter with the integration of artificial intelligence and machine learning. For example:

AI is a powerful solution, capable of processing large quantities of visual data without fatigue and identifying unexpected threats (such as shoplifting or the delivery of a suspicious package) that a human eye will not be able to detect.

To improve visibility, plan strategically, and make sound financial projections, FM teams are analyzing, understanding, and interpreting facility data to meet budget and long-term goals. This is semi-automatically sorted and it is extremely time-consuming. A lot of intuition is necessary to make sound decisions.

With AI you can automate these processes to generate quicker, more dependable, comprehensive data. By removing the intuition factor and eliminating human influence and error, AI FM software with limited manual research can:

Personalized insights provided by AI-powered analytics will ultimately allow your business to cut costs, prevent breakdowns, and keep both customers and employees satisfied.

FM may be the phase of managing a project that benefits most from AI in the coming years. FM has a lot of repetitive, time-consuming tasks. Introducing AI-in your processes, FM professionals will be able to:

AI in construction is improving a project's lifecycle and enabling the digitalization of construction material producers and/or distributors, it:

Implementing BIM can be daunting, but Driving Vision is here to help you at the pace you are comfortable with. Get started by getting in touch now

We act as your BIM coordinator

We Support your BIM IT

We Train & Coach you

We Innovate in Technology

We offer you and your projects’ partners a win-win solution based on a solid, long-lasting, fruitful relationship

You outsource the mundane & concentrate on what you do best